C2 PROJECT

C2 Photo Album

album:October 2018

Erle heats up a coupling rod joint, to help in extracting the taper pin.

Tender brake safety brackets: the starting point!

Chris polishes surface rust off one of the coupling rod bearing cover plates.

Caleb sets up a tender brake stretcher in the saw, ready to cut it to length.

Two old safety straps now the correct shape, and a new one with two of the three bends completed.

Sam sets up the next bend in a brake stretcher safety strap.

Measuring the lateral position of the driving crankpin relative to a parallel placed on the mounting faces for the cylinder and motion bracket.

Coupling rod parts all seprated at last! We'd been putting off this job for a few years.

Alasdair polishes surface rust off one of the coupling rod bearing cover plates. Sometimes it was less cold outside than it was in the shed!

Erle does some careful measuring of the connecting rods. This one is bent!

Andrew and Dave measure up the boiler backhead in preparation for designing the cab layout.

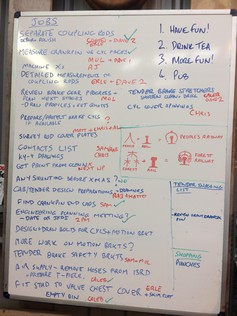

A whiteboard full of jobs. By the end of the working party we'd completed almost all of these, including number 4!